With a mission to provide future-proof logistics process automation, Vanderlande offers several solutions for material handling companies that include an AS/RS system, goods-to-picker (GtP) workstation, and pallet autonomous vehicles (AVs).

With a mission to provide future-proof logistics process automation, Vanderlande offers several material handling solutions, including an AS/RS system, a goods-to-picker (GtP) workstation, and pallet autonomous vehicles (AVs). Pick to Light Solution

The company’s Adapto shuttle-based automated storage and retrieval system (AS/RS) allows warehouse operators to handle an array of carton, tray, and tote sizes while roaming warehouse levels and aisles independently of lift platforms. Adapto sequences and prioritizes orders with ease, empowering warehouses to use one-to-one and direct connect pick stations, which increase the efficiency and accuracy of fulfillment operations. All of this is done on a system with a much smaller footprint than other shuttle-based systems. The result is that organizations can stock more SKUs (stock-keeping units) and increase the storage density of their facilities—all while increasing the velocity of their operations.

Vanderlande has also developed a goods-to-picker (GtP) workstation. Modular in design to provide maximum flexibility and a truly lean picking process, Vanderlande’s GtP workstations are highly intuitive and ergonomic. Customers gain improved pick performance on a system that requires minimal training, the company says. Seamlessly integrated with Adapto, the workstations also allow for one-to-one picking and highly refined sequencing for batch or discrete approaches.

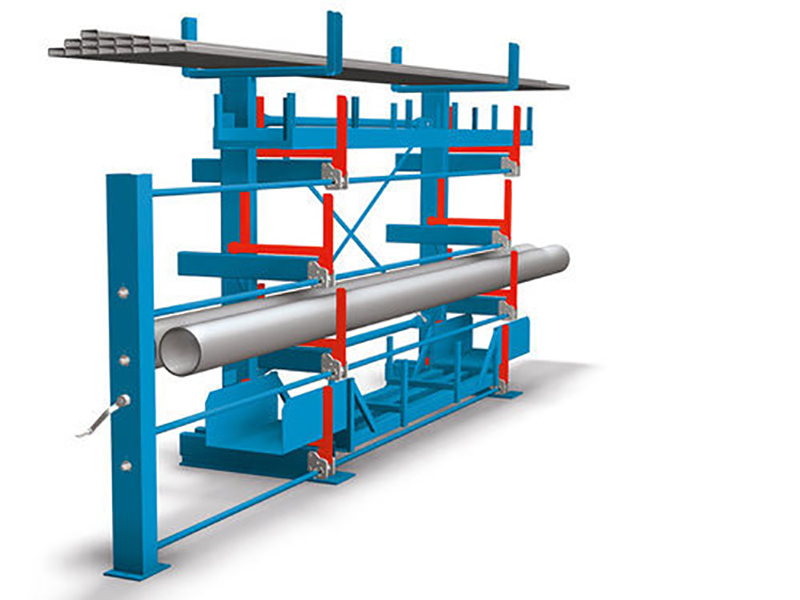

Four Way Pallet Shuttle Racking System Copyright ©2022. All Rights ReservedDesign, CMS, Hosting & Web Development :: ePublishing